40px

80px

80px

80px

Product Overview

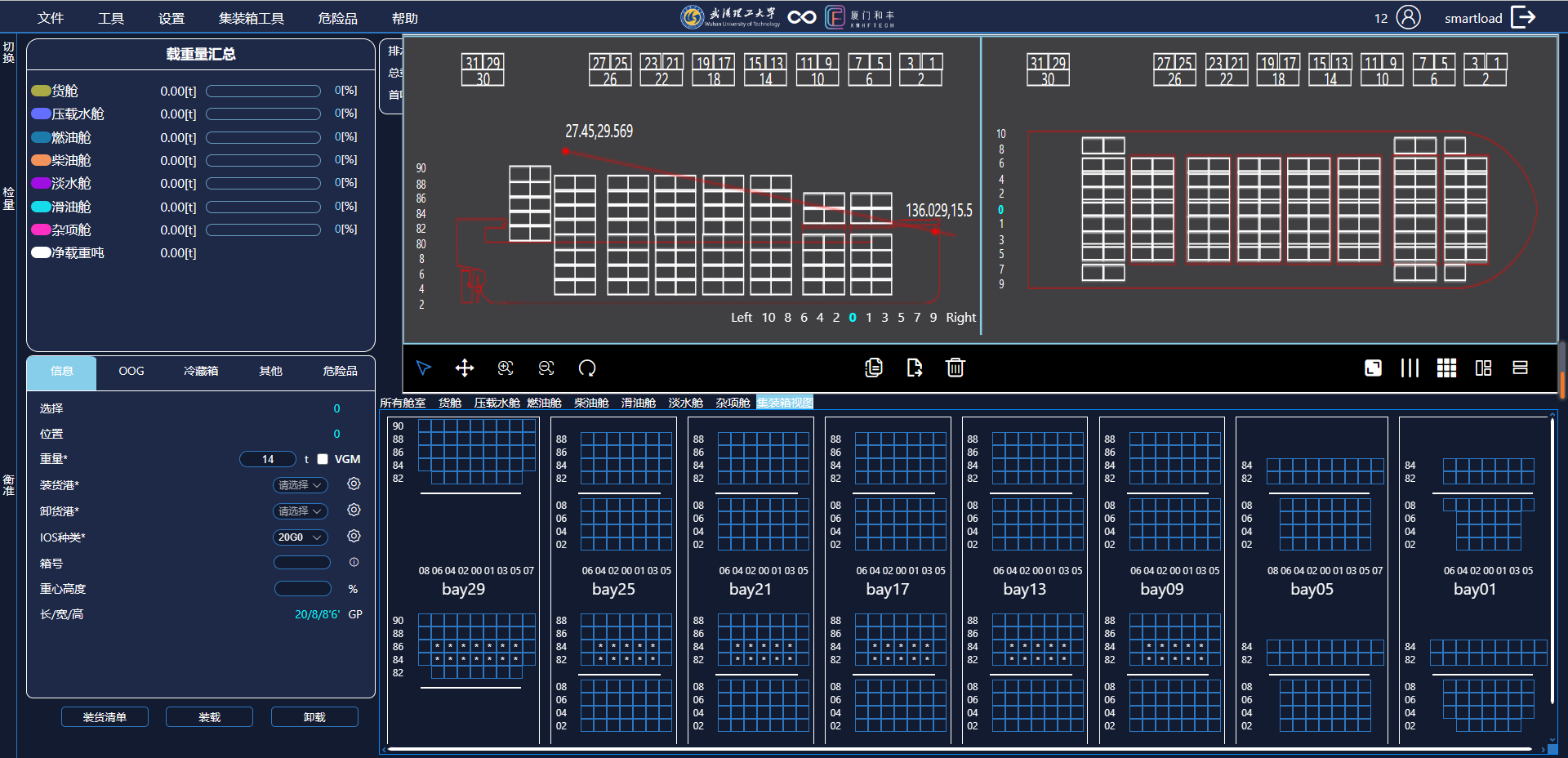

Hefonix-load 6000 cargo loading and stowage simulation training system is a next-generation intelligent cargo loading and stowage simulation training system based on 3D ship design models. Supporting a variety of ship types, including bulk carriers, container ships, and general cargo ships, the system is committed to providing a safe, efficient, and reliable training environment to improve crew training efficiency, enhance skills, and build stowage experience.

Product Features

The cargo loading and stowage simulation training system complies with international and domestic standards, including the Manila Amendments to the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers, 1978, and the Regulations on the Safety Supervision and Administration of the Carriage of Dangerous Goods on Ships. It offers the following features:

- Meets all classification society functional requirements for stowage simulation systems;

- Calculations are based on 3D ship design data, resulting in high accuracy;

- Supports damage flotation and strength analysis for any combination of compartments flooded;

- Efficient model slicing and simplification algorithms with proprietary intellectual property rights;

- Flotation and strength calculations with proprietary intellectual property rights;

- 3D visualization of the vessel, compartments, and cargo;

- Optimal stowage based on trim optimization.

Stowage simulator Features

The cargo loading and stowage simulation training system is developed using a web-based architecture, supporting cloud collaboration and multi-device access (computers, tablets, mobile phones, etc.). While offering extremely flexible configuration, its comprehensive functionality better meets the needs of crew members for online learning and verification. Its features include:

- Floatation calculation and verification;

- Stability calculation and verification;

- Strength calculation and verification;

- Self-checking capabilities, including cabin overload, deck cargo overheight/overload, and cabin overcapacity;

- Preview of ship loading and unloading, as well as ballast water exchange, providing dynamic indicators;

- Optimization of ship loading and unloading processes, ensuring smooth changes in ship bending moments throughout the entire loading and unloading process;

- Constant editing capabilities;

- Adding required weight to any location on the ship, distributing it longitudinally and transversely, and providing the coordinates of the center of gravity;

- Calculation results are presented to users in tabular, 2D, and 3D graphical formats.

In addition to the above functions, the Hefonix-load 6000 cargo loading and stowage simulation training system also provides customized services. We can customize the ship model and calculation module according to your needs, and provide supporting installation, commissioning and after-sales services to meet your exclusive needs.

About Us

As a global innovator in maritime simulation technology,Hefonix is dedicated to providing cutting-edge simulation training solutions to maritime, nautical, and related professional schools and institutions. Our team of 50+ professionals specializes in simulation technology R&D, maritime industry applications, and educational design. Guided by the principle of “flexible response to needs and innovative problem-solving,” we refuse to be bound by traditional standards and, through immersive simulation technology, make crew training more engaging, safer, and more realistic.

Our vision is clear and unwavering: unlock exclusive training modules and expand your training beyond traditional boundaries!

Hefonix-Cargo and Ballast 6000 Stowage Simulator is dedicated to providing a safe and efficient practical operation environment. Using digital means, it helps trainees develop key skills, improve stowage decision-making, and accumulate experience in a risk-free environment. This approach addresses the pain points of traditional stowage operations, such as low error tolerance, high labor costs, and high accident risks.

More40px

80px

80px

80px